RFID Labelling for the Warehouse Industry

Warehouses are increasingly using radio frequency identification (RFID) to complement or replace traditional barcode-drive processes. RFID tags and labels are applied to items and programmed with identification information. Compared to a barcode, the labels can be scanned and located remotely without having to immediately see the item or its label. RFID technology provides warehouses with an innova...

MAS

Mobile RFID Labelling for Warehouse Management

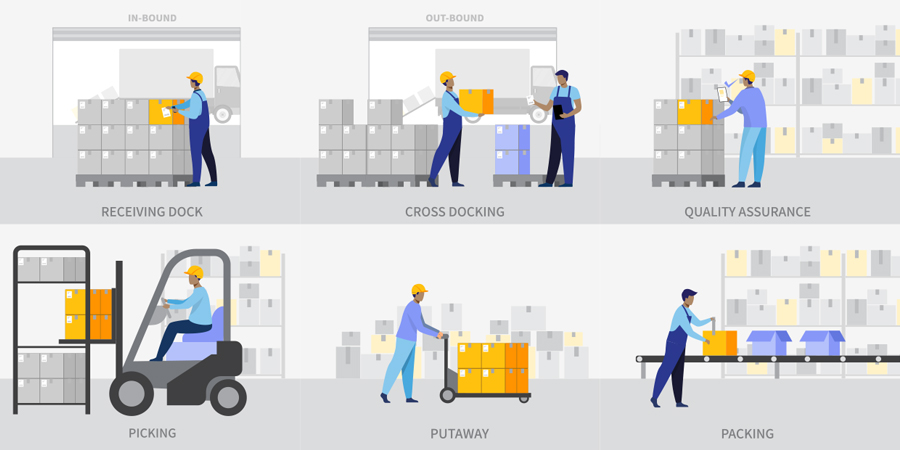

Warehouses of all sizes continue to adopt radio frequency identification (RFID) technology to dramatically streamline their data capture. RFID labelling offers several advantages for warehouse management over standard barcodes including inventory control and a reduction in errors. Desktop RFID printers may limit the benefits of RFID labelling. Due to the printer being fixed or stationary, it requ...

MAS

XL5-40 Exclusive Linerless Label Printer, A Game Changer for Cost and Environmental Solutions

Productivity

improvements, environmental regulation and TCO reduction are key points of all

businesses. Manufacturing and T&L are more focused on improving operations

like inventory management, shipping labelling, order releasing and packing.

Linerless labelling

solutions are a simple way to enhance the work process and reduce costs. Linerless

media is a...

Development in Label Printing

Since the introduction just-in-time delivery, asset management and enterprise productivity label printing technology has played a key role in product identification to allow easy asset documentation and tracking.

As there is increased pressure to improve the collection or data, many companies are moving away from traditional pen-and-paper processes and investing in technology to in...